Custom Solutions

You shouldn't have to choose from cookie cutter test machines if your test is anything but ordinary. Thanks to our modular design you have the power and flexibility to design and build a machine that fits your unique application and budget. You no longer have to pay for things that you will never need or use because those features come 'standard' with the mass-produced machines. We have thousands of products and we are continuously adding new products based on our customer's needs.

Modified and Custom Testing Capabilities

Can't find a system that meets your needs? It happens. That's why we give you the flexibility to co-engineer your own system! Need a design tweak? With our large number of standard products and a massive number of modular sub-assemblies, we can tweak an existing design quickly and economically. If you need a blank sheet of paper, start from scratch design, we can do that too. We have machines that are completely modular for when you need a simple tweak and we design optimized test machines for specific applications when you need a little more customization. Get exactly what you need, quickly and economically.

Need Something Special?

- Special size requirements

- Special grips or fixtures

- High/low force Static or Dynamic Load, Position and Strain control

- Environmental Chambers

- Multiaxial testing

- The list is endless!

Expert Application Engineering

After thousands of applications in over 50 countries, we have seen a thing or two. Our application engineers have experience in all things testing and testing all things. When you work with us, you get experienced engineers to solve your testing and budgetary challenges. That's just what we do.

Okay, we are biased but really we have done some amazing things, and we can help you do the same!

Ready to build your test machine?

Contact us by completing the form to help you design the right machine.

A Few Examples of Our Capabilities:

Airplane Landing Gear Test System

Technical Challenges

- Wide range of sample sizes requires 3-12 ft test space

- 18-inch test stroke

- Measure high forces at peak velocities

- <13-week delivery requirement

Budgetary Challenge

- A maintenance contractor of landing gear needs a low cost machine

Amazing Growing Test Machine

Technical Challenges

- A special clamping system allowing columns to be collapsed and shortened for transport and installation through an elevator. And expand to become a machine tall enough to test long test samples.

Budgetary Challenge

- The size requirements meant costly on-site installation.But thanks to some design work, we were able to build the machine outside of the room and saved the customer 2 full days of on-site installation costs.

2 for 1 Luer Tester

Technical Challenge

- Needed to be able to operate both combined axial torsional tests on a horizontal machine and some tests on a vertical machine.

Budgetary Challenge

- The customer was ready to buy two machines. We realized that with a few modifications we were able to combine two machines into one so the customer could perform both tests with fewer parts and a lower cost.

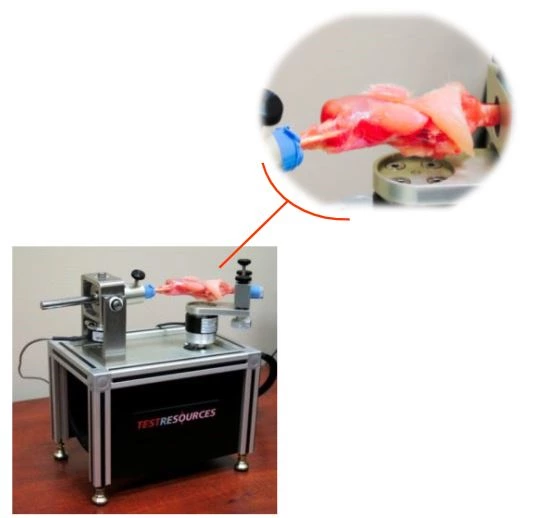

Rabbit Knee Tester

“I needed a method of measuring accurate data results for the angle and torque-free motion of a rabbit’s knee. TestResources took the time to understand what I needed and came up with an effective and budget-friendly solution.” Dr. Andrzej Fertala, Thomas Jefferson University

- Needed precise measurements accurate enough to differentiate a healthy rabbit knee from an injured knee

- Ability to analyze performance based on drug dosages and various periods of healing

- Allow a complex knee joint to freely flow in a natural angle when bending

Budgetary Challenge

- As a university research lab, obtaining funding can be a challenge